Last week I was in San Francisco for the inaugural Advancing Computational Building Design conference featuring two days of speakers, panels, and discussions centered around the growing importance of technology in architecture, engineering, and construction. The conference placed a particular emphasis on computational design -- the use of coding, visual programming, data analytics, and other methods for more informed design and implementation.

I had the pleasure of speaking on a panel titled "Reimagining the Culture & Contractual Relationships Between Owners, Architects, & Contractors to Enable Further Adoption of Computational Design" alongside Aubrey Tucker, Innovative Technology Developer at Stantec and Thomas Whisker, VDC Project Manager at Turner Construction. While my colleagues focused on the intricacies of contracts, BIM disclaimers, and model fidelity, I took the opportunity to share how Tocci Building Co. is approaching projects differently. As Owner's Project Manager on several projects, we have the unique authority to bring the Virtual Design and Construction (VDC) team in earlier on the project for design facilitation and a simultaneous quantity takeoff and pricing process. At Tocci, computational design further enhances what we are able to do.

Panel from left to right: Kyle Martin, Aubrey Tucker, Thomas Whisker. Moderator: Jorge Barrero. Photo credit: Ryan Cameron.

With more traditional project delivery VDC implements vigorous MEP/FP coordination, resulting in confirming RFIs for near-instantaneous response time and less tedious paperwork. A major advantage in a collaborative approach to project delivery/coordination is that potential conflicts are identified earlier in the project. Resolving issues before they are time sensitive and at a time when the owner can stll make decisions about the cost of the project -- rather than have those decisions made for them by construction schedule -- will ultimately deliver a final product much more closer to the initial design intent.

The key takeaway from ACBD for me was the overwhelming consensus that technology is crucial to the future success of the AEC industry. I attend several conferences per year and never have I encountered a more unified, passionate crowd of interdisciplinary professionals who are consistently pushing the boundaries of possibility and setting an example of true innovation through their work.

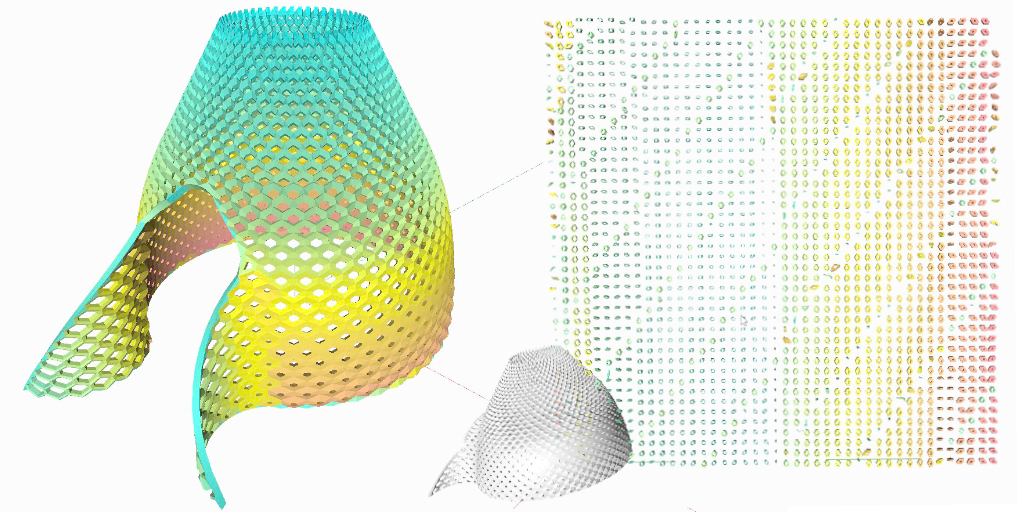

Later that evening I delivered one of two featured presentations to the San Francisco Dynamo User Group celebrating their 2-year Anniversary at AIA San Francisco. The SFDUG was formed with the same purpose as the Dynamo-litia Boston User Group I founded at the Boston Society of Architects to help educate and promote the use of Dynamo visual programming in local AEC communities. My presentation "Cost in Translation: Bridging the Gap Between Designers & Contractors" highlighted some of my efforts at Tocci including several day-to-day implementations of Dynamo and longer term projects such as the Sasaki WinterLight Pavilion and Union Point Comfort Station. The crowd at this event was super receptive and it was fun to meet so many new faces from the opposite side of the country!

Image credit: Ryan Cameron

Unfortunately there was an error recording my portion of the presentation, however you can view the slide deck HERE.

Make sure to check out the other presentation Computational Design Increases Value to Project Managers & Designers | How to gain Buy-In by colleague Ryan Cameron, Architect at DLR Group.

In the end it was a busy couple of days on the West Coast but I thoroughly enjoyed the opportunity to exchange knowledge and promote the importance of computational design and data-driven processes in the future of the AEC industry.